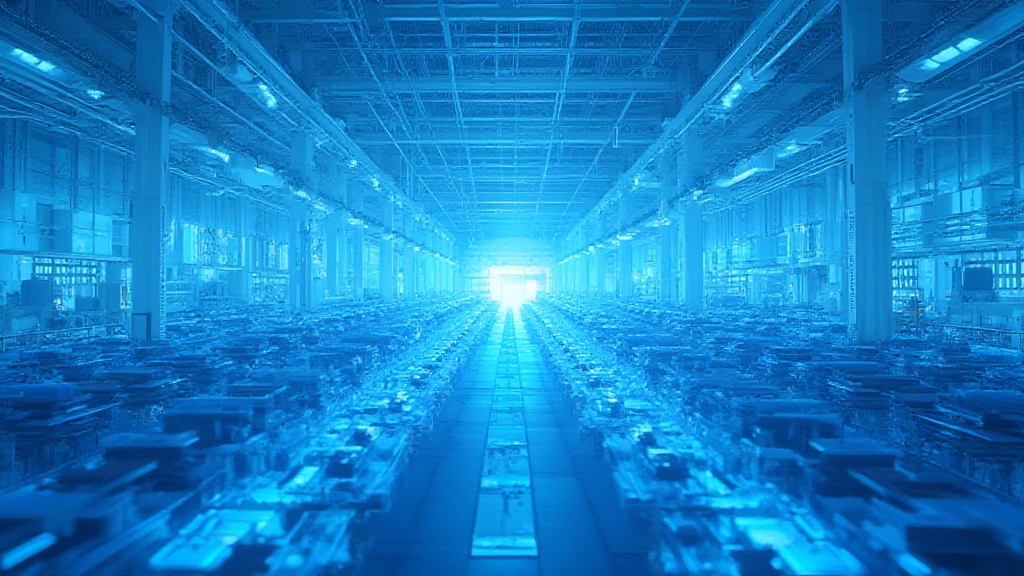

Manufacturing ecosystems within solar production have achieved remarkable scale, reaching 580 GW global capacity during Photovoltaic facilities operate continuously through advanced capacity planning systems, revolutionizing clean energy infrastructure deployment worldwide.

Gigafactory development initiatives transform regional manufacturing capabilities through automated production lines and supply chain logistics optimization.

Wafer fabrication technologies and polysilicon refineries establish new efficiency metrics for sustainable energy generation.

Material sourcing strategies and quality testing protocols ensure consistent output across global operations.

Production Excellence and Innovation

Silicon ingot processing facilities utilize industrial scaling methods to maximize throughput optimization. Component assembly operations incorporate:

- Automated cell production systems

- Precision thin-film deposition

- Advanced crystalline processing

Click here to learn more about: carbon footprint solar panel carbon footprint reduction marbella

Understanding Global Distribution Networks

Distribution networks span continents, with Chinese manufacturing dominance reaching 80% of worldwide capacity. Supply chain logistics drive strategic diversification through emerging renewable hubs and modernized facility expansion.

Regional clusters demonstrate significant growth trajectories:

India: 50 GW annual production target by 2025

United States: 40 GW manufacturing capacity in development

European Union: 30 GW planned capacity expansion

Industrial parks integrate vertical integration practices while maintaining rigorous quality assurance standards. Performance monitoring systems and workflow management protocols optimize operational efficiency across international manufacturing zones.

How Supply Chain Logistics Impact Production

Supply chain logistics shape the entire solar manufacturing landscape through complex material flows and regional dependencies. Global polysilicon manufacturing capacity reached 2 million metric tons during 2023, demonstrating unprecedented industrial scaling across renewable hubs.

Material sourcing requirements drive production decisions, while distribution networks connect manufacturing stages through carefully planned logistics systems.

Regional Manufacturing Dependencies

Polysilicon refineries concentrated in Asia control 75% of worldwide production, creating specific chain resilience considerations for global markets.

Manufacturing ecosystems develop around these regional clusters, optimizing workflow management through:.

- Component assembly coordination between facilities

- Energy-efficient plants positioned near material sources

- Logistical planning integration with quality testing protocols

Wafer fabrication facilities strategically locate near polysilicon sources, leveraging material processing efficiencies to reduce downstream costs. Performance monitoring systems track supply vulnerabilities while industrial optimization enhances distributed production networks.

Exploring Modern Gigafactory Development Trends

Gigafactory development represents the next evolution in solar manufacturing excellence. Vertical integration strategies have enabled 40% cost reductions through streamlined production processes. Automation systems handle 85% of manufacturing steps, revolutionizing throughput optimization capabilities.

Advanced Manufacturing Integration

Facility modernization combines technological advancement with operational metrics to achieve superior results:.

Key Innovation Features:

– AI-powered line automation monitoring

– Automated material handling protocols

– Integrated quality assurance systems

Production efficiency improvements of 25-30% annually demonstrate the effectiveness of modern manufacturing ecosystems. Standardization protocols maintain consistent output quality while reducing operational costs through sophisticated monitoring systems and process controls.

Key Supply Chain & Manufacturing Facts

- Global polysilicon manufacturing reached 2 million metric tons in 2023

- Asian polysilicon refineries control 75% of worldwide production capacity

- Gigafactory automation systems manage 85% of manufacturing processes

- Modern facilities achieve 25-30% production efficiency gains annually